In the high vacuum chamber using oil diffusion pump or molecular pump, there are certain residual gases, more than 80% of which are water vapor, oil vapor and other gases with high boiling point. However, the mechanical pump has low ability to remove residual gases and takes a long time. And the residual gas is also the pollution source of the workpiece, which affects the quantity and quality of the product.

Water vapor and oil vapor are the main harmful gases in the field of vacuum coating and high vacuum obtaining.

(1) Due to the existence of water vapor and oil vapor, the vacuum pumpdown time becomes longer, the vacuum system can not quickly reach the target vacuum degree, and the production efficiency decreases; The higher the vacuum degree required, the greater the environmental humidity, and the more obvious the impact.

(2) At the same time, the existence of water vapor and oil vapor will lead to the decline of film firmness, the failure of multi-layer coating, uneven color and other phenomena affecting product quality.

(3) Under certain conditions, water vapor will ionize and produce oxygen, which will oxidize the target and change the coating color.

VaporCold (Polycold) is the best choice to solve the above problems.

The working principle of the VaporCold is to make the water vapor molecules condense on the ultra-low temperature surface of the cryocoil according to the principle of Meissner trapping, effectively adsorb the water vapor, and achieve the purpose of capturing water vapor.

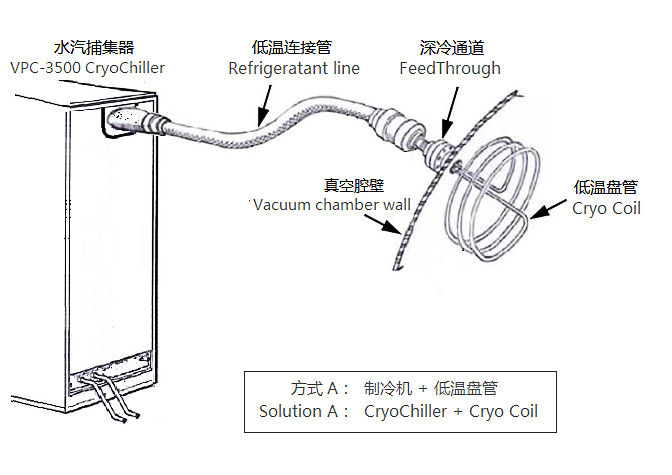

Specific application of VaporCold: place a low-temperature coil below -100 ℃ in the vacuum chamber or at the pump port of the oil diffusion pump, and quickly capture the water vapor of the vacuum system through the low-temperature surface, so as to greatly shorten the vacuumizing time (60-90% of the vacuumizing time can be shortened), and obtain a clean vacuum environment.

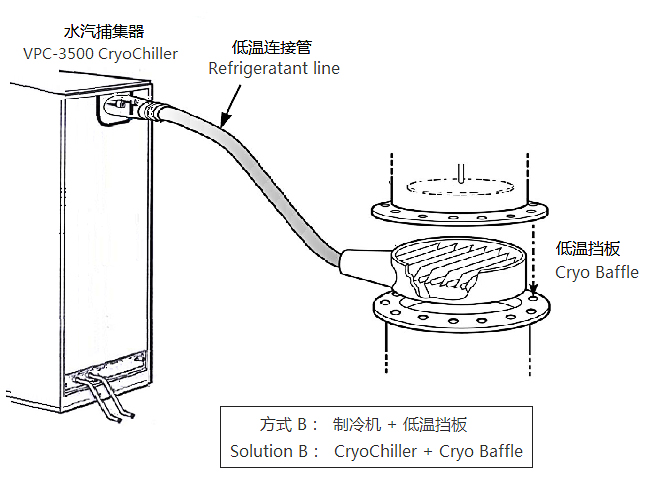

In practical application, according to different positions of low-temperature surfaces, they can be generally divided into two applications:

A. Low temperature coil (cryo coil)

The low temperature coil is often installed between the high valve and the vacuum chamber or in the vacuum chamber, and in the upper and lower rooms of the winding coating. It is very suitable for plastic low-temperature coating, winding coating and other coating materials with a large amount of outgassing. The low-temperature coil shall have the function of heating and defrosting to restore the coil to the normal temperature before breaking the vacuum each time, so as to avoid frost caused by the low-temperature coil absorbing a large amount of water vapor from the atmosphere and affecting the vacuum pump down time of the next product cycle.

B. Low temperature baffle (cryo baffle)

It is placed between the pump inlet and high valve of the oil diffusion pump. Its main function is to prevent the oil and gas backflow of the oil diffusion pump, and also to accelerate the pumpdown speed and improve the vacuum degree. Since the system is in a vacuum state, the defrosting function is not required.

As required, the low-temperature coil and low-temperature baffle can be installed separately or at the same time.

Main functions of vaporcold water vapor cryochiller:

Shorten vacuum pumpdown time and improve coating quality

Main features of VaporCold water vapor cryochiller:

* Rapid water vapor trapping, shorten the vacuum pumpdown time by 25-90%;

* Improve coating quality, for the best films, better adhesion and more reproducible deposition;

* Fast cooling, cool to -100℃ within 3 minutes, with a minimum of -150℃;

* Fast defrosting, defrost to 20℃ within 3 minutes ;

* The refrigeration system is optimized to cool down again within 3 minutes;

* With industrial PLC and touch panel, Process data logging is supported;

* International brand refrigeration compressor, environmental friendly refrigerant blend;

* International standard refrigeration port, which can be designed as single or two-way load outputs;

* Display and logging of inlet temperature and outlet temperature of single or two-way load;

* Display and logging of internal temperature, water cooling temperature,discharge temperature and discharge pressure;

* The defrosting temperature can be set freely, and will be prompted automatically after defrosting;

* Alarm protection for high discharge temperature and pressure;

* Alarm protection for insufficient water cooling and high water temperature;

* The valve box is placed in front,convenient for operation;

* Local mode and remote mode, convenient for combination control;

* RS485 communication interface to facilitate connection to upper computer.

The -135℃ VaporCold developed and produced by Coolium instrument adopts core technology, reliable design, imported brand refrigeration compressor and refrigeration accessories, environmental friendly mixed refrigerant and automatic cascade refrigeration. Fast cooling speed, high efficiency, low temperature and convenient maintenance. Its design and manufacture are in step with the international technical level, and its performance index reaches or even exceeds that of similar imported models, which can realize the direct replacement Polycold models.

Coolium instrument provides a complete water vapor trapping solutions to help customers improve production efficiency, reduce production costs, improve process performance, and improve product quality and quantity.