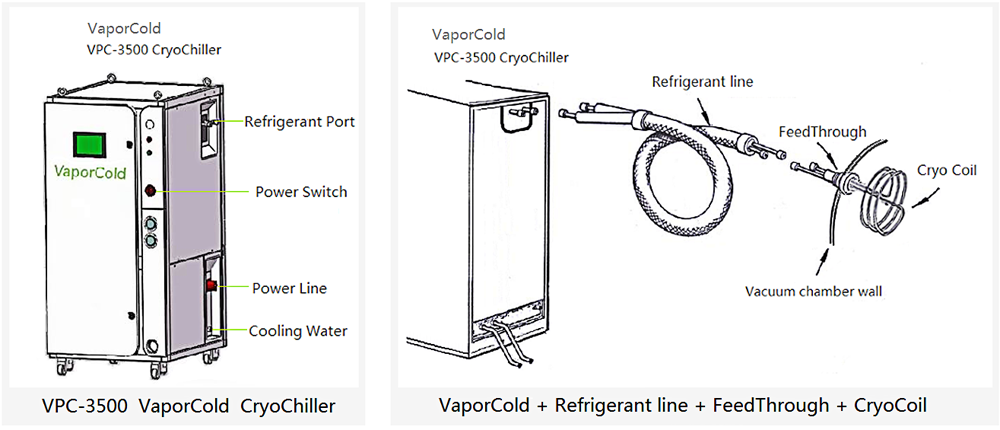

| Cryo Coil | |

The low-temperature coil has many forms and is the key component for capturing water vapor. It is generally installed in the vacuum chamber and uses the ultra-low temperature surface of the coil to capture and adsorb water vapor. | ||

The common material of low-temperature coil is copper pipe, which is snake shaped, spiral shaped, or welded on the copper back plate. Coils of any shape can be customized according to user requirements. | ||

| Refrigerant Line | |

The standard length is 3M, and the appropriate length can be prefabricated according to actual needs. It contains 2 copper pipes and external insulation tube. CPI or VCR connectors are used at both ends of the connecting pipe to connect the cryochiller or feedthrough. | ||

If necessary, stainless steel bellows can be selected to replace copper pipe. | ||

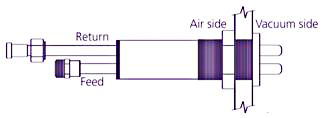

| FeedTrough | |

The standard feedthrough is the channel for refrigerant to enter and leave the vacuum chamber wall, and ensures the cooling capacity isolation and vacuum isolation. It can be divided into single tube in and out type and double tube in and out type. | ||

For single tube in and out type, a through hole with a diameter of 1 inch is generally reserved in the vacuum chamber wall. | ||

For double tube in and out type, a through hole with a diameter of 2 inches is generally reserved in the vacuum chamber wall. | ||

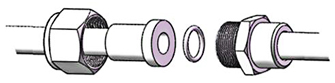

| Standard Coupling | |

The feed and return of low-temperature refrigerant and the refrigeration port of the water vapor cryochiller need to match the low-temperature connecting tube and the feedthrough of the coating machine. The sealing performance under ultra-low temperature is very important. | ||

The standard Parker coupling can be directly compatible with the polycold model. | ||

Optional flared refrigeration connector or VCR refrigeration coupling. | ||

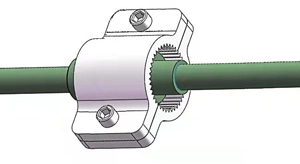

| Thread Locking | |

The improved copper nut combination can effectively prevent the refrigerant leakage of key components such as the refrigeration hand valve, solenoid valve, pressure gauge and sensor of the equipment due to the use of traditional nuts. | ||

The patented refrigeration joint locking device can prevent refrigerant leakage caused by loose joint threads. | ||

| Remote Connector | |

The main control functions (standby, cooling and defrosting) of the water vapor cryochiller are connected to the remote control of the coating machine. It can also send out 1 or 2 channels of temperature analog standard signals. | ||

The standard 37 pins socket can be directly compatible with the polycold model. | ||

Users can also use RS485 communication to realize remote control function. |